Rotation

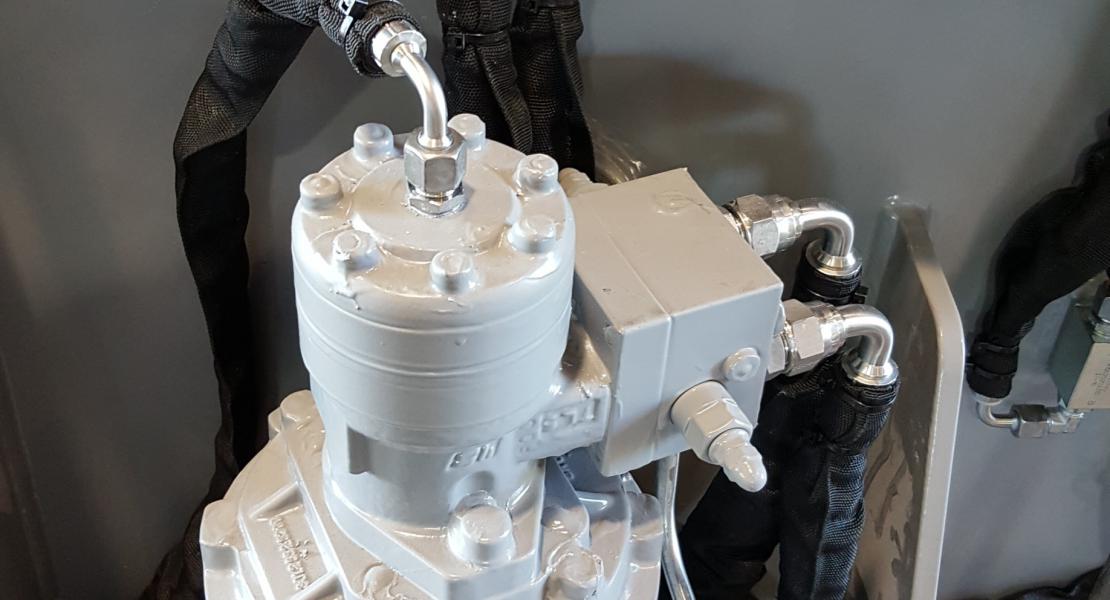

A powerful rotation system with a slewing bearing and gearboxes enables precise work and a better distribution of loads on the base. This slew solution provides the best rotation method for the operator. All gearboxes are supplied with a negative brake that restricts crane movements during operations and boat movements.

The rotation system can be also supplied with special valves for motion control for special applications.